I think there are many old soldiers starting to embrace their prior service more. It kind of goes along with the healing process.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knife picture thread

- Thread starter TXCOONDOG

- Start date

Harris hawker

LSB Member

Really like the wood handles.

The the burl look is my favorite.

The the burl look is my favorite.

You went dark on us for a couple months. You probably missed the free AR that TLM gave all the active members for sticking with him.

Ratdog68

LSB Official Story Teller

LSB TURKEY BUZZARD PRESERVATION SOCIETY

SUS VENATOR CLUB

LoneStarBoars Supporter

Thought I would share one of my projects. I designed this blade many years ago thinking that it would be a good design for cleaning large redfish or other large salt water fish. Its not at all flexible, intended to have enough backbone to cut through the tough ribs of a large fish. I had it cut out and shaped when I was re-assigned to Japan. While over there, I didn't have the assets to get it heat treated and thought I would have to wait a few years till I got back to the States. I was introduced to a Japanese fellow who spoke fluent English. In the mean time, I had discovered a Japanese knife maker who spoke absolutely no English. Well, between me and my translator, we were able to get across to the knife maker that I needed the knife heat treated and final polish. You can see what the result was. I put the scales on and waited to get back home to try it out. It was years before I got to catch a decent size fish to see if my baby would work, and unfortunately, it was a bust. So....into the drawer it went for many more years. This year, I got tired of seeing it sit there so I brought it with me on my deer hunt. Helloooo...it turned out to be the most efficient skinning and quartering knife I have ever used. It's razor sharp and still has enough back bone to cut through joints like a scalpel. Now to find a sheath for it to make it more useful.

Thick enough leather so as not to pierce the sheath while stowing, a good welt to keep from cutting the stitching while sheathing. That little choyl (?) for the fore finger is a good spot for a rivet to effect a nestle/friction point to keep it secure w/o a strap. I'd lean toward a dangler type sheath, thought being, easily swing to/fro when bumped/brushed against things while walking.

Last edited:

Thick enough leather so as not to pierce the sheath while stowing, a good welt to keep from cutting the stitching while sheathing. That little choyl (?) for the fore finger is a good spot for a rivet to effect a nestle/friction point to keep it secure w/o a strap. I'd lean toward a dangler type sheath, thought being, easily swing to/fro when bumped/brushed against things while walking.

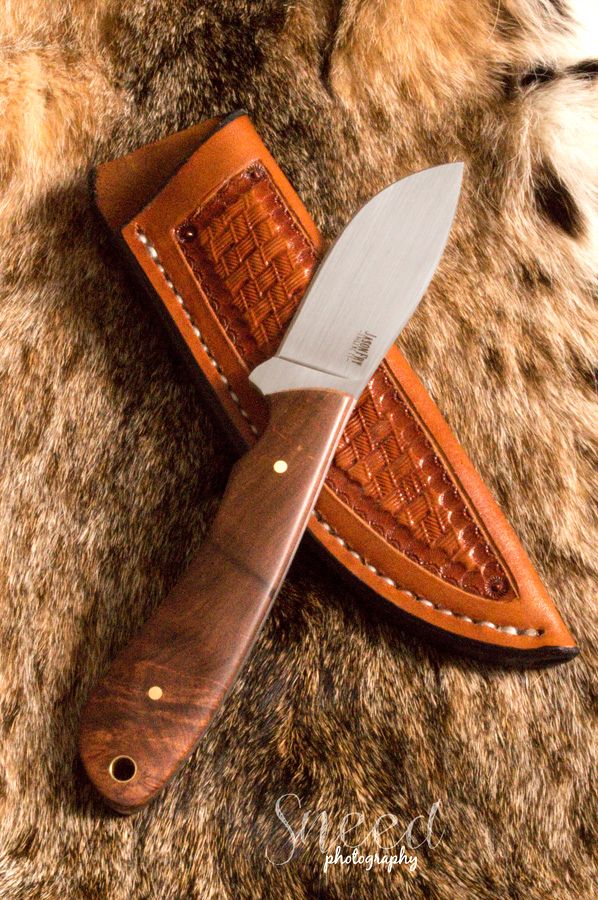

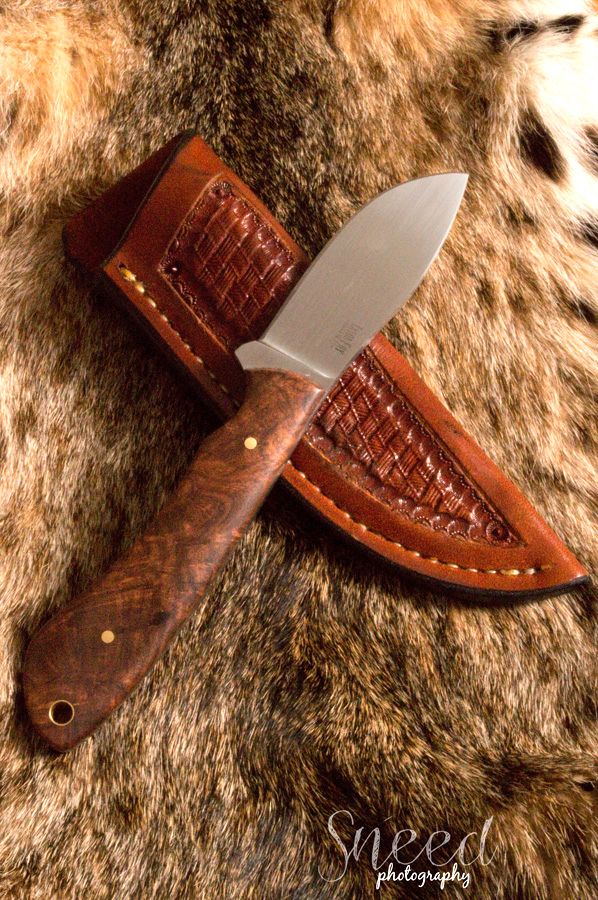

A friend made this sheath for me recently. Sorry about the size of the picture, it shrunk.

Ratdog68

LSB Official Story Teller

LSB TURKEY BUZZARD PRESERVATION SOCIETY

SUS VENATOR CLUB

LoneStarBoars Supporter

Dang, love seein' the details of others' efforts.

Just finished my first custom knife last night. The blade is an old Nicholson file, the scales were made from a whitetail shed I found about 2 years ago. Copper pins and a brass lanyard sleeve. Blade polished to 200o grit. It's far from perfect, but this one was basically a test run to see if I was capable of making one. I now have a pile of rasps and plan to get into custom knife making.

Yes sir. I intended to leave more but they faded out a little while I was polishing the blade.Lookin' sharp. Lookin' like some of the file serrations remain for effect?

Did you anneal the file before you ground it then heat treated it after?

Yes sir, annealed to red hot and then air cooled, blade profiled with grinder and files, then blade heated to red hot and quenched in vegetable oil, then wire brushed clean, then in the oven at 400 degrees to temper for 2 sessions of 2 hours each, then edge finished, polished and sharpened and handles shaped and epoxied/pinned in place and sanded to final shape.Did you anneal the file before you ground it then heat treated it after?

You did a really nice job. I have a few rasps that I want to make a couple knives with. Hope mine come out as good as yours did.

Thank you sir. I was worried at first that I might screw it up, but then I really got into it and ended up doing a good job. The main thing to remember is be patient. Everyone liked it so much that people are already requesting knives. I've got 4 blanks shaped out already and 6 more ready to cut and shape. It's an addicting hobby.You did a really nice job. I have a few rasps that I want to make a couple knives with. Hope mine come out as good as yours did.